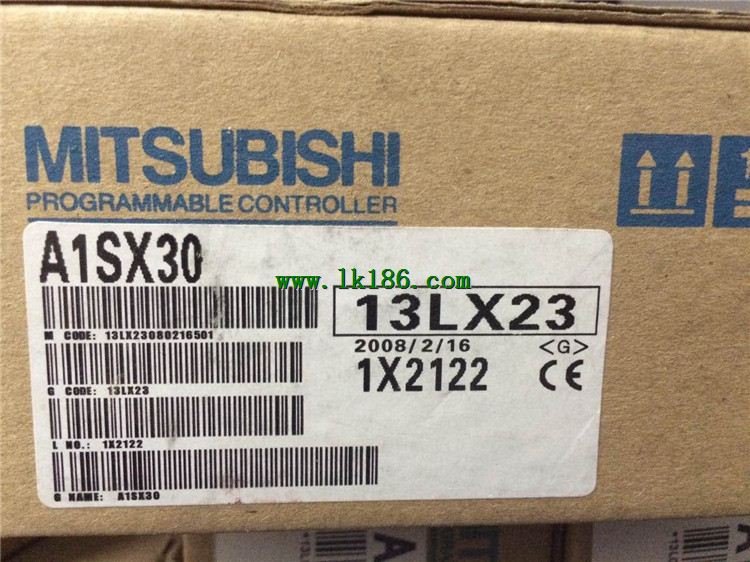

A1SX30 MITSUBISHI A1SX30

Brand:

MITSUBISHI

Name: Input module

Model: A1SX30

Input type: AC/DC.

Input points: 16 points.

Input voltage: 12/DC24.

Input current: 4.2/8.6.

Connection mode: terminal row.

Common common point: 16.

The instruction list programming language is a programming language similar to assembly language mnemonic,

As well as assembly language by the operation code and the number of operations.

In the case of the computer for the PLC handheld programmer compile user program.

At the same time, the programming language of the instruction list corresponds to the ladder diagram programming language,

In PLC programming software can be converted to each other. Figure 3 is the instruction sheet corresponding to the ladder diagram of figure 2PLC.

The characteristics of instruction table programming language is used to represent mnemonic operation function,

Easy to remember, easy to grasp;

In the handheld programmer on the keyboard using the mnemonic representation, easy to operate, can be programmed in computer;

There is a one-to-one correspondence between the ladder diagram and the ladder diagram. Its characteristics are basically consistent with the ladder diagram language.

...More relevant models >>>>

Name: Input module

Model: A1SX30

Input type: AC/DC.

Input points: 16 points.

Input voltage: 12/DC24.

Input current: 4.2/8.6.

Connection mode: terminal row.

Common common point: 16.

The instruction list programming language is a programming language similar to assembly language mnemonic,

As well as assembly language by the operation code and the number of operations.

In the case of the computer for the PLC handheld programmer compile user program.

At the same time, the programming language of the instruction list corresponds to the ladder diagram programming language,

In PLC programming software can be converted to each other. Figure 3 is the instruction sheet corresponding to the ladder diagram of figure 2PLC.

The characteristics of instruction table programming language is used to represent mnemonic operation function,

Easy to remember, easy to grasp;

In the handheld programmer on the keyboard using the mnemonic representation, easy to operate, can be programmed in computer;

There is a one-to-one correspondence between the ladder diagram and the ladder diagram. Its characteristics are basically consistent with the ladder diagram language.

Enter 32 points.

5mA DC24V.

Response time: 0.3ms.

32 point 1 public.

Output 32 points.

DC12/24V.

Leakage current: 0.1mA OFF.

Response time: 1ms. 32 point 1 public.

Protection function.

Surge.

40 pin connector.

Switching value, also known as logic, refers to only two values, 0 or 1, ON or OFF.

It is the most common control, it is the advantage of PLC control,

Is also the most basic application of PLC MITSUBISHI A1SX30 A1SX30

Switch volume control is designed to,

According to the current input combination of the switch quantity and the history of the input sequence,

So that PLC generates the corresponding switching output,

In order to make the system work in a certain order.

So, sometimes also known as the order control MITSUBISHI A1SX30.

And sequential control is divided into manual, semi-automatic or automatic.

And the control principle is decentralized, centralized and hybrid control three. AnS, QnAS bus connection, the reader to write program 2 channel connection.Axis of control: 1.

A1SD75 series components show the MITSUBISHI in the manufacture and design of CNC, frequency converter,

Integrated technical experience in servo system and PLC MITSUBISHI A1SX30.

These components have a wealth of features that are sufficient to meet the highest requirements in the application of positioning control.

A1SD75M, SCC net compatible controller, SSC network is the MITSUBISHI servo system control network MITSUBISHI Input module.

In this network, the MR-H-13, MR-J-B, and MR-J2 servo amplifiers can be connected to a controller via a network system,

The connection is replaced by a pulse sequence and a voltage signal MITSUBISHI Input module. Interface: RS232C.

Transmission distance: 15 meters.

A1SJ71UC24-R2/R4/PR computer communication components can be relied on external intelligent devices such as computers and PLC for communication, the components are as follows:

Full / half duplex transmission,

4 special communication protocols,

No protocol and bidirectional mode,

Protocol selection switch function,

The optional baud rate, the highest 19 MITSUBISHI Input module. 2K,

Since the echo diagnostic test. PLC station distance: 500M.

Cable type: coaxial cable.

The function of the MELSECNET interface module is to connect the main CPU PLC to the MELSECNET data communication system.

As long as the switch on the component to set,

Can determine the CPU PLC is as the main station or in situ station.

There are two modules available for selection: one is the connection of the optical cable network and the network of the coaxial cable.

For a ANSCPU, up to only a piece of interface components can be inserted, A2ASCPU can be inserted 2.

The popularization and application of PLC programming has been developed rapidly in our country,

It has been widely used in all kinds of mechanical equipment and production process of electrical control devices,

All walks of life have emerged a large number of application of PLC transformation of the results of the equipment.

Understand the working principle of PLC, have the ability to design, debug and maintain the PLC control system,

Has become the basic requirements of modern industry for electrical technicians and engineering students.

The instruction list programming language is a programming language similar to assembly language mnemonic,

As well as assembly language by the operation code and the number of operations.

In the case of the computer for the PLC handheld programmer compile user program.

At the same time, the programming language of the instruction list corresponds to the ladder diagram programming language,

In PLC programming software can be converted to each other. Figure 3 is the instruction sheet corresponding to the ladder diagram of figure 2PLC.

The characteristics of instruction table programming langguage is used to represent mnemonic operation function,

Easy to remember, easy to grasp;

In the handheld programmer on the keyboard using the mnemonic representation, easy to operate, can be programmed in computer;

There is a one-tto-one correspondence between the ladder diagram and the ladder diagram MITSUBISHI A1SX30 A1SX30. Its characteristics are basically consistent with the ladder diagram language.

5mA DC24V.

Response time: 0.3ms.

32 point 1 public.

Output 32 points.

DC12/24V.

Leakage current: 0.1mA OFF.

Response time: 1ms. 32 point 1 public.

Protection function.

Surge.

40 pin connector.

Switching value, also known as logic, refers to only two values, 0 or 1, ON or OFF.

It is the most common control, it is the advantage of PLC control,

Is also the most basic application of PLC MITSUBISHI A1SX30 A1SX30

Switch volume control is designed to,

According to the current input combination of the switch quantity and the history of the input sequence,

So that PLC generates the corresponding switching output,

In order to make the system work in a certain order.

So, sometimes also known as the order control MITSUBISHI A1SX30.

And sequential control is divided into manual, semi-automatic or automatic.

And the control principle is decentralized, centralized and hybrid control three. AnS, QnAS bus connection, the reader to write program 2 channel connection.Axis of control: 1.

A1SD75 series components show the MITSUBISHI in the manufacture and design of CNC, frequency converter,

Integrated technical experience in servo system and PLC MITSUBISHI A1SX30.

These components have a wealth of features that are sufficient to meet the highest requirements in the application of positioning control.

A1SD75M, SCC net compatible controller, SSC network is the MITSUBISHI servo system control network MITSUBISHI Input module.

In this network, the MR-H-13, MR-J-B, and MR-J2 servo amplifiers can be connected to a controller via a network system,

The connection is replaced by a pulse sequence and a voltage signal MITSUBISHI Input module. Interface: RS232C.

Transmission distance: 15 meters.

A1SJ71UC24-R2/R4/PR computer communication components can be relied on external intelligent devices such as computers and PLC for communication, the components are as follows:

Full / half duplex transmission,

4 special communication protocols,

No protocol and bidirectional mode,

Protocol selection switch function,

The optional baud rate, the highest 19 MITSUBISHI Input module. 2K,

Since the echo diagnostic test. PLC station distance: 500M.

Cable type: coaxial cable.

The function of the MELSECNET interface module is to connect the main CPU PLC to the MELSECNET data communication system.

As long as the switch on the component to set,

Can determine the CPU PLC is as the main station or in situ station.

There are two modules available for selection: one is the connection of the optical cable network and the network of the coaxial cable.

For a ANSCPU, up to only a piece of interface components can be inserted, A2ASCPU can be inserted 2.

The popularization and application of PLC programming has been developed rapidly in our country,

It has been widely used in all kinds of mechanical equipment and production process of electrical control devices,

All walks of life have emerged a large number of application of PLC transformation of the results of the equipment.

Understand the working principle of PLC, have the ability to design, debug and maintain the PLC control system,

Has become the basic requirements of modern industry for electrical technicians and engineering students.

The instruction list programming language is a programming language similar to assembly language mnemonic,

As well as assembly language by the operation code and the number of operations.

In the case of the computer for the PLC handheld programmer compile user program.

At the same time, the programming language of the instruction list corresponds to the ladder diagram programming language,

In PLC programming software can be converted to each other. Figure 3 is the instruction sheet corresponding to the ladder diagram of figure 2PLC.

The characteristics of instruction table programming langguage is used to represent mnemonic operation function,

Easy to remember, easy to grasp;

In the handheld programmer on the keyboard using the mnemonic representation, easy to operate, can be programmed in computer;

There is a one-tto-one correspondence between the ladder diagram and the ladder diagram MITSUBISHI A1SX30 A1SX30. Its characteristics are basically consistent with the ladder diagram language.

...More relevant models >>>>

Related download

Last one:

Last one:  next one:

next one: